16-2000mm PE pipe extrusion line

Application

The HDPE pipe line plastic is used for producing all kinds of HDPE pipes, such as: agricultural water supply & discharge piping system, architectural water supply & discharge piping system, gas supply piping system, etc.

Pressure pipes

Water supplying and transportation pipes

Gas distribution and transportation pipes

Mine field pipes

Agriculture irrigation pipes

Discharge pipeline for chemical and food fields

Protection and conduit pipes for electric cables and communication wires

Fishpond edge guardrail pipes

Description

Hdpe pipe line machine consists of hdpe pipe extruder machine, pipe dies, calibration units, cooling tank, haul-off, cutter, stacker/coiler and all peripherals.

Hdpe plastic pipe extrusion line produces pipes with the diameter from 20 to 1600mm in various material, such as HDPE, PP-H etc.type specimen book.

Hdpe pipe machine is a preferred for ductwork system of gas, water pipe and agricultural irrigation pipe between city and village.

Pipe Vacuum Tankflow Chart of Hdpe Pipe Extrusion Line

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder→ color band extruder → mould and calibrator → vacuum calibration machine → cooling tank→ haul-off machine → cutting machine → stacker(Winding machine)

Features and Advantages

1. PE pipe making machine is developed by Polestar based on European advanced technology and R&D experience of plastic machinery for many years, advanced design, reasonable structure, high reliability, high degree automation of hdpe pipe production line.

2. Extruder with special barrel feeding structure can largely improve extrusion capacity.

3. Accurate temperate control, good plasticization, stable operation.

4. PE pipe production line adopts PLC control system, realizing synchronization and automation.

5. Human-computer interface is easy to operate, convenient and reliable.

6. Spiral and lattice basket type die dead for choice.

7. Changing some parts of the line can also realize two-layer and multi-layer co-extrusion.

8. Changing some parts of the line can also produce PP, PB pipes.

Technical Data

| Model | Pipe range (mm) | Extruder | Die Head | Total power (kW) |

Output Capacity (kg/h) |

| PE-63 | 16-63 | SJ65 | Single outlet | 100 | 80-120 |

| PE-110 | 20-110 | SJ65 | Single outlet | 150 | 150-250 |

| PE-160 | 50-160 | SJ75 | Single outlet | 180 | 150-250 |

| PE-250 | 75-250 | SJ75 | Single outlet | 230 | 250-350 |

| PE-450 | 160-450 | SJ90 | Single outlet | 380 | 350-450 |

| PE-630 | 250-630 | SJ120 | Single outlet | 550 | 700-800 |

| PE-800 | 500-800 | SJ150 | Single outlet | 800 | 900-1100 |

| PE-1200 | 710-1200 | SJ150 | Single outlet | 1000 | 1000-1300 |

| PE-1600 | 1000-1600 | SJ150 | Single outlet | 1200 | 1200-1500 |

Single Screw Extruder

Based on 33:1 L/D ratio for screw design, we have developed 38:1 L/D ratio. Compared with 33:1 ratio, 38:1 ratio has advantage of 100% plasticization, increase output capacity by 30%, reduce power consumption up to 30% and reach almost linear extrusion performance.

Simens Touch Screen and PLC

Apply program developed by our company, have English or other languages to be input into the system.

Spiral Structure of Barrel

Feeding part of barrel use spiral structure, to ensure material feed in stable and also increase feeding capacity.

Special Design of Screw

Screw is designed with special structure, to ensure good plasticization and mixing. Unmelted material can not pass this part of screw.

Air Cooled Ceramic Heater

Ceramic heater ensure long working life. This design is to increase the area which heater contact with air. To have better air cooling effect.

High Quality Gearbox

Gear accuracy to be ensured 5-6 grade and lower noise below 75dB. Compact structure but with high torque.

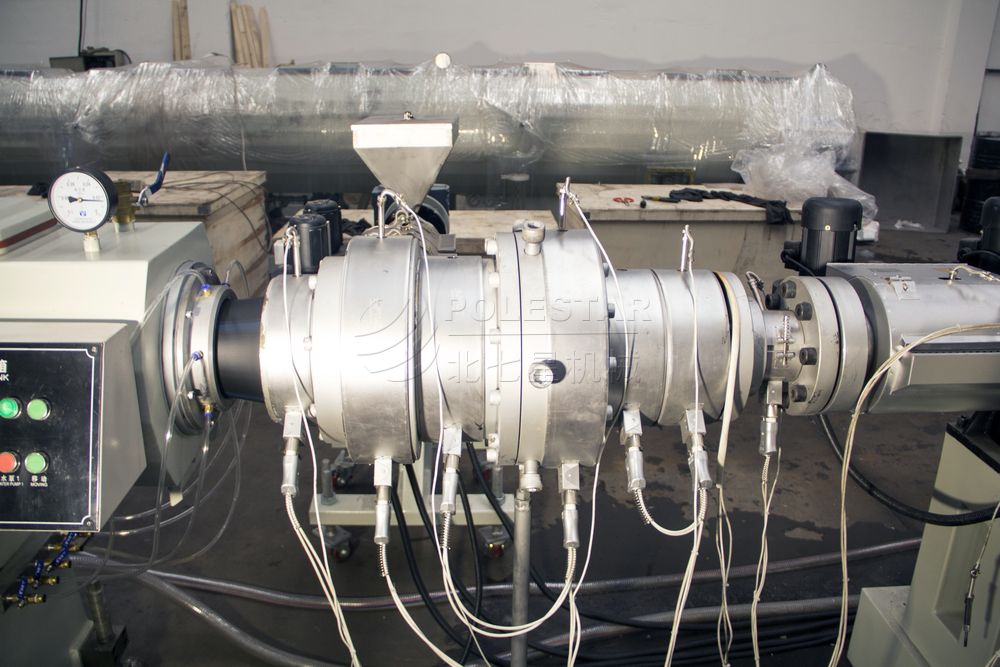

Extrusion Die Head

Extrusion die head apply spiral structure, each material flow channel is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly. Die head structure is compact and also provide stable pressure, always from 19 to 20Mpa. Under this pressure, pipe quality is good and very little effect on the output capacity. Can produce single layer or multi-layer pipe.

Moving Device of Die Head

For big size die head, moving device can move die head forward and back, also adjust the height of die head. Operation is fast and easy.

Die Head Rotary Device

For big size die head with rotary device, die head can rotate by 90 degree. When changing bush, mandrel, die head will turn 90 degree. Can use crane to lift and change bush and mandrel. This way is very convenient.

Heat Exhausting Device

This device is added on die head to produce big and thick pipe. To exhaust heat inside the pipe and cooling pipe inside wall. The heated exhausted can be used to dry the raw material.

Cooling Device for Core

When produce pipe with big diameter and wall thickness, we will use cooling water or oil together with cooling fan to cool the core of die head to avoid over heating and ensure good material quality.

Vacuum Tank

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. We use double-chamber structure. First chamber is in short length, to ensure very strong cooling and vacuum function. As calibrator is placed in the front of first chamber and pipe shape is formed mainly by calibrator, this design can ensure quick and better forming and cooling of pipe.

Strong Cooling for Calibrator

With special cooling system for calibrator, which can have better cooling effect for pipe and ensure high speed. Also with good quality spray nozzle to have better cooling effect and not easy blocked by impurities.

Better Support for Pipe

For big size pipe, each size have its own semicircular support plate. This structure can keep pipe roundness very well.

Silencer

We place silencer on the vacuum adjust valve to minimize noise when air come into the vacuum tank.

Pressure Relief Valve

To protect the vacuum tank. When vacuum degree reach maximum limitation, the valve will open automatically to decrease vacuum degree to avoid broken of tank. Vacuum degree limitation can be adjusted.

Double Loop Pipeline

Each loop with water filtering system, to provide clean cooling water inside tank. Double loop also ensure continuous providing of cooling water inside tank.

Water, Gas Separator

To separate the gas water water. Gas exhausted from upside. Water flow into the downside.

Full Automatic Water Control

With mechanical temperature control to have accurate and stable control of water temperature.

Whole water inlet and outlet system is controlled full automatic, stable and reliable.

Centralized Drainage Device

All water drainage from vacuum tank are integrated and connected into one stainless pipeline. Only connect the integrated pipeline to outside drainage, to make operation easier and faster.

Cooling Tank

Cooling tank is used to cool pipe further.

Pipe Clamping Device

This device can adjust pipe roundness when pipe comes out from the vacuum tank.

Water Tank Filter

With filter in the water tank, to avoid any big impurities when outside water comes in.

Quality Spray Nozzle

Quality spray nozzles have better cooling effect and not easy blocked by impurities.

Pipe Support Adjusting Device

Support with adjustment function to support pipe with different diameters.

Pipe Support Device

Especially used when producing pipe with big diameter and wall thickness. This device will provide additional support to heavy pipes.

Haul Off Unit

Haul off unit provides sufficient traction force to pull pipe stably. According to different pipe sizes and thickness, our company will customize traction speed, number of claws, effective traction length. To ensure match pipe extrusion speed and forming speed, also avoid deformation of pipe during traction.

Separate Traction Motor

Each claw has its own traction motor, in case when one traction motor stop working, other motors can still working. Can choose servo motor to have bigger traction force, more stable traction speed and wider range of traction speed.

Claw Adjustment Device

All claws are connected to each other, when adjusting position of claws to pull pipe in different sizes, all claws will move together. This will make operation faster and easier.

User Friendly Design

With Siemens hard ware and user friendly software designed by our company. Have synchronized function with extruder, make operation easier and faster. Also customer can choose only some of claws to work to pull much smaller pipes.

Separate Air Pressure Control

Each claw with it own air pressure control, more accurate, operation is easier.

Cutter

Cutter controlled by Siemens PLC, working together with haul off unit to have precise cutting. Customer can set the length of pipe they want to cut. Multi-feed-in actions for the accomplishment of one cutting process (protect blades and saws, prevent from blade and saws stuck for thick pipe and cut face of pipe is smooth).

Universal Clamping Device

Apply universal clamping device for different pipe sizes, no need to change clamping device when pipe size changes.

Saw and Blade Interchangeable

Some cutters are equipped with both saw and blade. Saw and blade cutting are interchangeable for different pipe sizes. Also, saw and blade can work together for special requirement.

Central Height Adjustment

With electrical adjusting device for clamping device. Operation faster and easier. With limit switch to ensure safety.

Stacker

To support and unload pipes. Length of stacker can be customized.

Pipe surface protection

With roller, to protect pipe surface when moving pipe.

Central Height Adjustment

With simple adjustment device to adjust the central height for different pipe sizes.

Coiler

To coil pipe into roller, easy for storage and transportation. Usually used for pipe below size 160mm. Have single station and double station for choice.

Use of servo motor

Can choose servo motor for pipe displacement and winding, more accurate and better pipe displacement.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.