High Precision PVC Pipe Mould

Description

Plastic extrusion molds are made of high quality alloy steel, the quenched and tempered treatment, flow surface polishing chromium plating processing.Sizing material for copper alloy;Range of pipe:: 20,32,40,50,63,75,90,110,125,150,200,225,250,315,400.etc. Have Basic mould,mouth mould, core mould, have mould turn over car.

Application

Applied for manufacture of caliber PVC,UPVC supply and drain pipes.

High Quality Material

Apply high quality material for extrusion die head. Die head has high strength and will not deform during long time use under high temperature condition.

Competitive Advantage

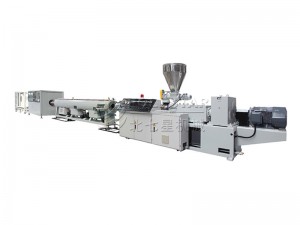

1. GF series plastic pipe production line is mainly used in manufacture of the plastic PVC pipes with tube diameters and wall thickness, which are used for water supply and drainage in the field of agriculture and construction.

2. This line is composed of conical twin-screw extruder, vacuum calibration table, haul-off, cutter, stacker etc.

3. The extruder and the haul-off adopt the quality AC frequency conversion control device.

4. The vacuum pump and motor adopt the famous brand.

5. The haul-off have two-claw, three-claw, four-claw, six-claw.

6. It may choose the saw blade cutting type or the planet cutting production efficiency.

7. Our company may equipped the special device for the manufacture of the inner wall spiral coil and core layer blister according to the client’s requirement.

Characteristics

| Specification | GF-125 | GF-160 | GF-250 | GF-500 | GF-630 |

| Max. pipe diameter(mm) | 125 | 160 | 250 | 500 | 630 |

| Total power of auxiliary machine (kw) | 13 | 14 | 19 | 27.5 | 35 |

| Cooling water consumption (m3/h) | 3 | 6 | 6 | 9 | 12 |

| Compressed air pressure (Mpa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Plastic Extrusion Molds

Extrusion die head apply bracket structure, each material flow channel is placed evenly. Each channel is after heat treatment, mirror polishing and chroming to ensure material flow smoothly. Die head is modular design, easy for changing pipe sizes, assembling, dismantle and maintenance. Can produce single layer or multi-layer pipe.

Moving Device of Die Head

For big size die head, moving device can move die head forward and back, also adjust the height of die head. Operation is fast and easy.

Die Head Rotary Device

For big size die head with rotary device, die head can rotate by 90 degree. When changing bush, mandrel, die head will turn 90 degree. Can use crane to lift and change bush and mandrel. This way is very convenient.

CNC Processing

Every part of extrusion die head is processed by CNC to ensure precision.

High Quality Material

Apply high quality material for extrusion die head. Die head has high strength and will not deform during long time use under high temperature condition.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.